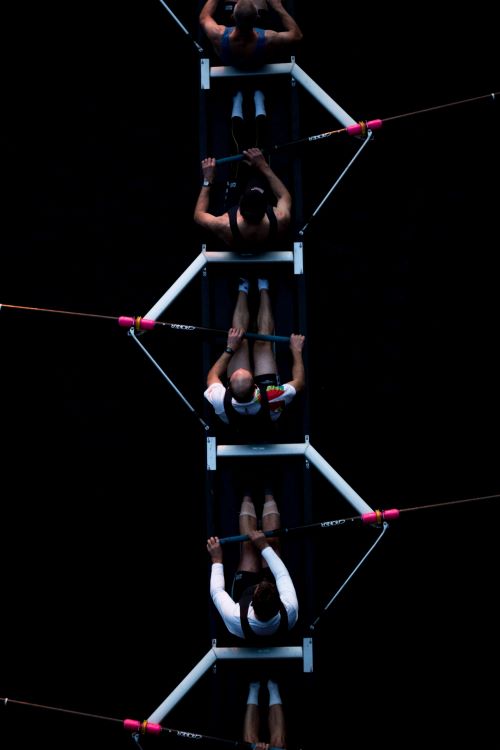

Spring Industry

Spring Industry

Isolated Documents

Information Duplication

Lack of General Database

Production Level

Lack of Planning and Forecasting of Occupancy

Absence of Effective Production Capacity Utilization Levels

Duplicated and/or Lost Manufacturing Orders

Product Identification Errors

Production Quantities Adjusted on the Shop Floor Based on Momentary Sentiment and Perception of Need

Lack of Resource Requirement Calculation

Quality Level

Lack of Tracking/Recording of Internal NOK Production (Defect Typology)

Lack of Tracking/Recording of Scrap Production

Manual Laboratory Records without Treatment

The solution found was implementation of the Wetrack production management platform integrated with ERP SAGE X3, enabling the digitization of all production processes, eliminating paper records, and making all information available in a single, interconnected database with easy access to important information.

Real-time monitoring on all equipment

Equipment Management and Monitoring

Dynamic and automatic production planning

Real-time monitoring of all manufacturing orders

Production cost analysis based on consumption during the Work Order

Quality Production Control and Recording (Laboratory)

Real-time printing of finished product identification

Business Intelligence Reports

Up to 10% increase in machine utilization time

Up to 7% improvement in OEE

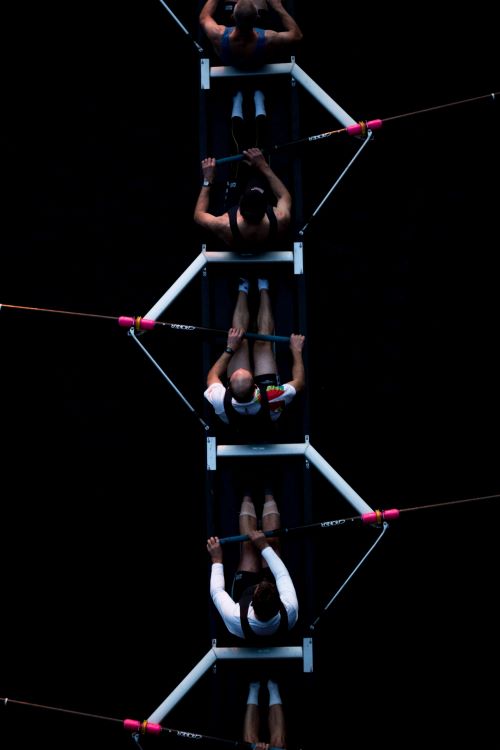

Mold Industry

Mold Industry

The challenge of Group TJ Moldes was the creation of an integrated management information system, with the aim of integrating all data and processes of the TJ group organization into an ecosystem consisting of a tool or set of tools, in order to eliminate the isolation of production from the rest of the business. With the introduction of integrated tools capable of planning and monitoring production processes, it is possible to reduce downtime/waste, increase production capacity, improve production cycles, and control costs.

The solution was the implementation of the Wetrack production management platform integrated with Primavera ERP for procurement, and with the ELO attendance system. This enabled the digitization of all production processes, eliminating paper records and making all information available in a single integrated information system, with mechanisms that allow for better and faster decision-making.

Equipment Monitoring

Real-time Dashboards

Monitor speed, efficiency, and production stops

Total/Overall Equipment Efficiency (OEE)

Analyze production times, production stops, and setup

Production and production stops history

Measurement of machine hours and operator hours

Management Indicators

Custom Reports tailored to needs

Quoting and Supplier Orders

Detailed production cost control vs. budgeted

Control of all information related to customer orders and production

Control of quotation requests and supplier orders

Automatic generation of consumption and associated costs integrated with production and Primavera ERP

Custom Reports tailored to needs